Turn O Mill Components

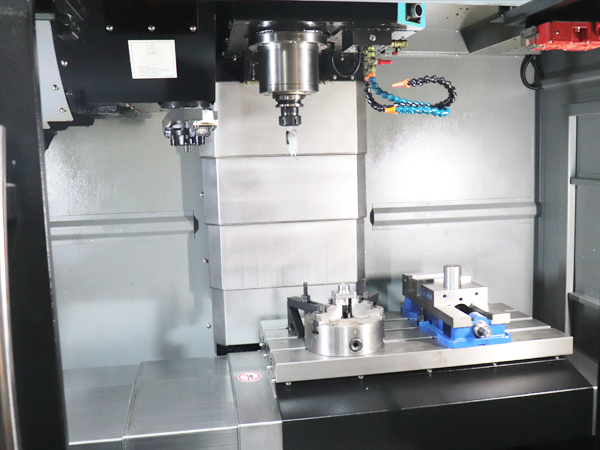

A Computer Numerical Control (CNC) Turn-O-Mill, often referred to as a CNC turning center or lathe-mill combination, is a sophisticated machining tool that seamlessly integrates turning and milling operations. This versatile machine is widely utilized in manufacturing to produce intricate components with precision and efficiency.

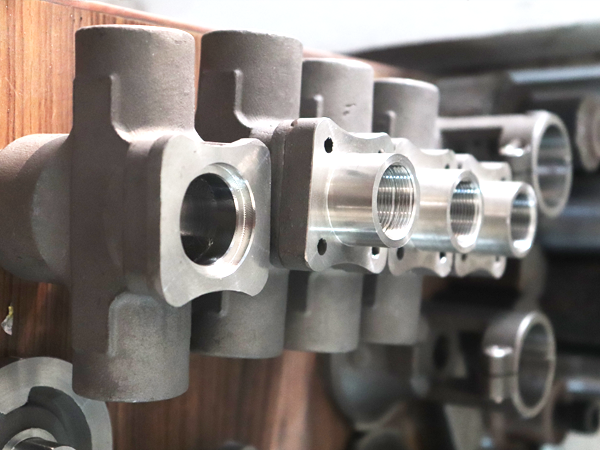

At the core of the CNC Turn-O-Mill is the Lathe Component, which facilitates turning operations. The workpiece is securely mounted on a spindle that rotates against cutting tools, allowing for the creation of cylindrical or conical shapes. The lathe component is equipped with multiple axes, enabling intricate and contoured geometries to be machined.

Complementing the lathe functionality is the Milling Component. This part of the machine allows for additional machining processes such as drilling, grooving, and contouring. The milling component typically features a variety of tools that can be automatically swapped during machining operations, offering versatility in shaping the workpiece.

The heart of the CNC Turn-O-Mill is its CNC Control System, a sophisticated interface that allows operators to program and control the machine’s movements. The CNC system interprets digital instructions, enabling precise coordination of the lathe and milling components. Operators can input detailed specifications, including toolpaths, speeds, and depths, ensuring accurate and repeatable machining.

Tool changes are facilitated by an integrated Tool Changer, a feature that enhances efficiency by automating the swapping of cutting tools during machining processes. This reduces downtime and allows for the seamless transition between turning and milling operations.

The Workholding System is a critical component that ensures the workpiece is securely held in place during machining. Various chucking systems or collets are employed to grip and stabilize the workpiece, allowing for precise and consistent machining results.

The CNC Turn-O-Mill is often equipped with a Coolant System to manage the heat generated during machining. This system not only enhances tool life but also contributes to maintaining the dimensional accuracy of the machined components.

In summary, the CNC Turn-O-Mill is a highly integrated machining tool that combines turning and milling operations in a single machine. From the lathe and milling components to the CNC control system and tool changer, each element contributes to the machine’s ability to produce intricate and precise components with efficiency and versatility.

Other Products