VMC Components

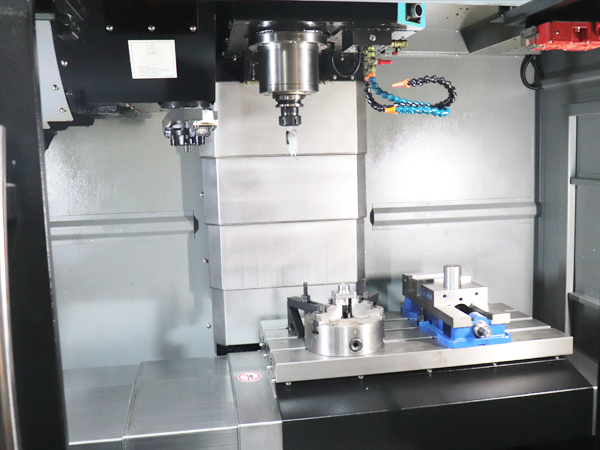

A Vertical Machining Center (VMC) is a sophisticated machine tool used in manufacturing processes to precisely shape and carve materials. Its efficiency and accuracy stem from the synergy of various components working seamlessly together.

At its core is the Base, a robust foundation providing stability, crucial for maintaining accuracy during high-speed machining. Rising vertically from the base, the Column supports essential components and houses the spindle head.

The Spindle Head is a pivotal component, accommodating the spindle that holds and rotates cutting tools. Adjustable along the Z-axis, it determines the depth of cuts, influencing the precision and speed of machining. Complementing this is the Tool Changer, an automated system that allows rapid tool swaps, enhancing operational efficiency. Modern VMCs often feature advanced tool changers capable of holding an array of tools for diverse applications.

Guiding the movement along the Y-axis is the Saddle, mounted on the column’s guideways. It supports the table, which moves horizontally along the X-axis, facilitating precise positioning of the workpiece. The Table is a flat surface where the workpiece is secured during machining, and its movement allows for intricate cuts.

The Control Panel, housing the CNC (Computer Numerical Control) system, serves as the operator’s gateway to the VMC. This interface allows for the input of commands, programming of tool paths, and real-time monitoring of machining processes. The CNC system, driven by software, orchestrates the movement of the machine’s axes and the rotation of the spindle, ensuring accuracy and repeatability.

Ensuring optimal functioning and longevity are components such as the Coolant System and Way Covers. The coolant system dissipates heat generated during machining, while way covers protect critical components like guideways and ball screws from debris, ensuring smooth operation.

In synergy, these components make a VMC a versatile and efficient tool for various machining applications. From the foundational base to the sophisticated CNC system, each element contributes to the precision, speed, and reliability that define the capabilities of a Vertical Machining Center.

Other Products