CNC Turning Components

Computer Numerical Control (CNC) turning is a machining process that plays a pivotal role in modern manufacturing, offering precision and efficiency in the production of cylindrical components. This versatile technology has revolutionized the way intricate parts are produced, allowing for automation and high repeatability.

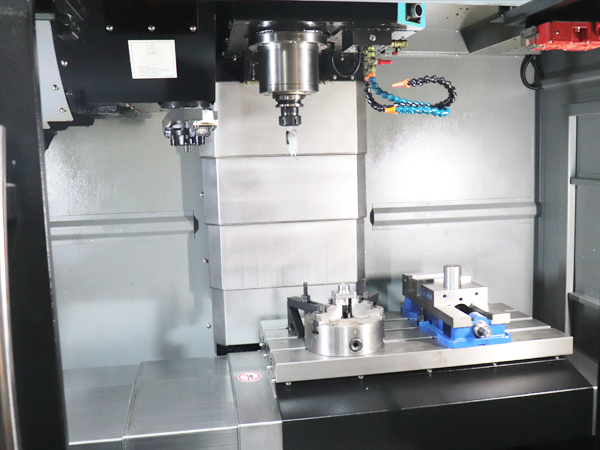

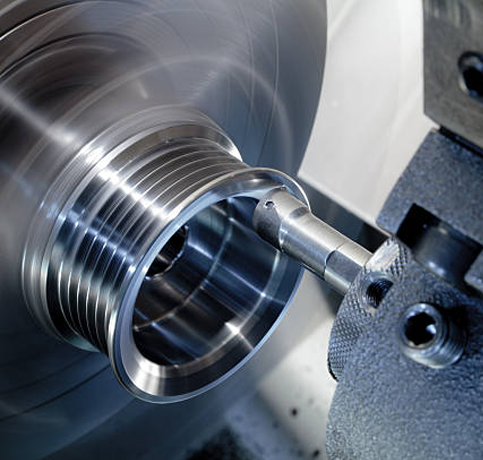

At the core of CNC turning is the CNC Lathe, a sophisticated machine tool designed to rotate a workpiece rapidly while cutting tools are applied to it. The workpiece is secured on a spindle and rotated against various cutting tools, allowing for the creation of intricate shapes, contours, and threads. CNC turning is particularly adept at producing components with rotational symmetry, such as shafts, bolts, and bushings.

The CNC turning process is driven by a sophisticated CNC Control System. This computerized interface allows operators to program the machine with precise instructions, specifying toolpaths, cutting speeds, and depths. The CNC system interprets these digital instructions, guiding the movement of the cutting tools in a highly coordinated and controlled manner. This level of automation ensures accuracy, consistency, and the ability to replicate complex geometries with ease.

One of the key features of CNC turning is its adaptability to a wide range of materials. Whether working with metals, plastics, or composites, CNC turning machines can efficiently shape materials into intricate components, maintaining tight tolerances and surface finishes. The versatility of CNC turning makes it a fundamental process in industries ranging from aerospace and automotive to electronics and medical devices.

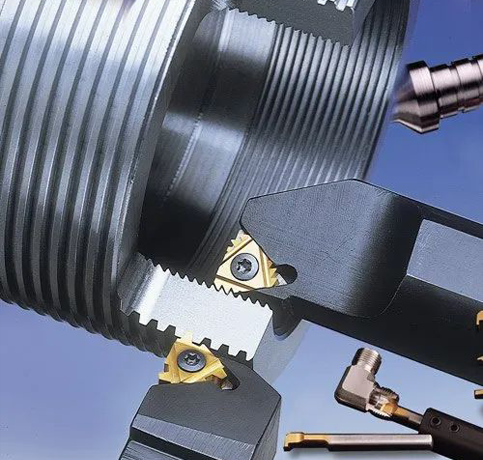

The Tooling System in CNC turning is designed to hold and manipulate various cutting tools. Modern CNC lathes often come equipped with automatic tool changers, allowing for seamless transitions between different tools during the machining process. This feature enhances efficiency and reduces downtime.

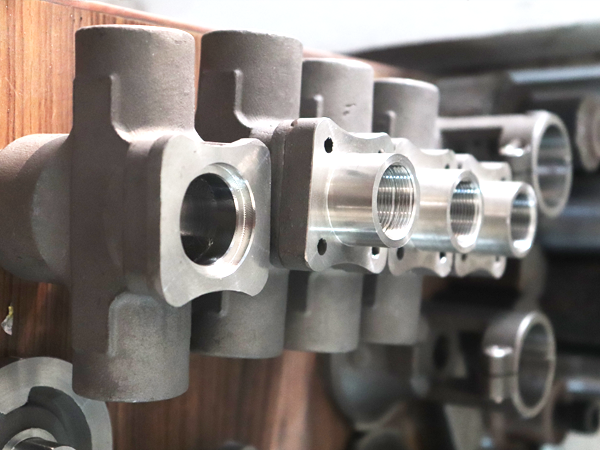

The Workholding System is another crucial element in CNC turning. Workpieces are held securely in place during machining to ensure stability and precision. Various types of chucks, collets, or fixtures are used to grip the workpiece based on its size, shape, and material.

The CNC turning process can include additional features such as live tooling, which enables milling operations on the rotating workpiece, expanding the capabilities of the CNC lathe.

In summary, CNC turning is a highly advanced machining process that combines precision, automation, and versatility. From the CNC lathe and control system to tooling and workholding systems, each component contributes to the efficiency and accuracy of the turning process, making it a cornerstone in modern manufacturing.

Other Products