Measuring Facility

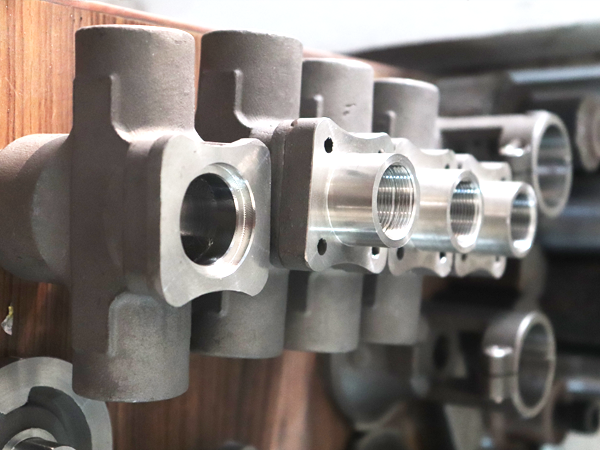

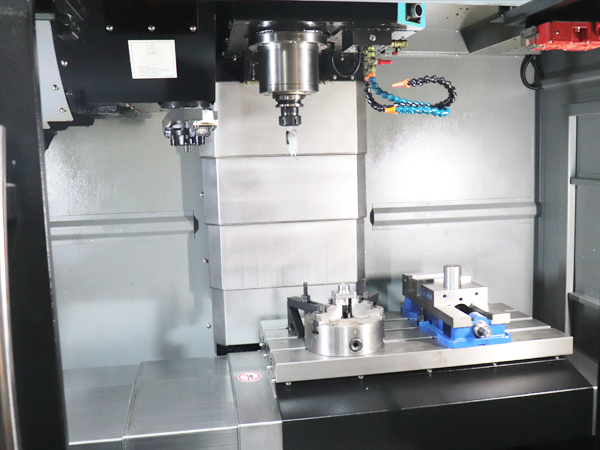

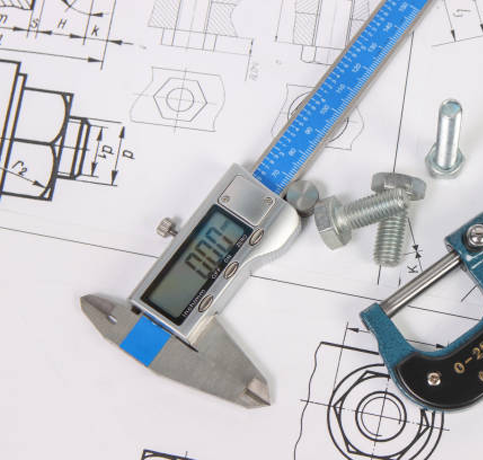

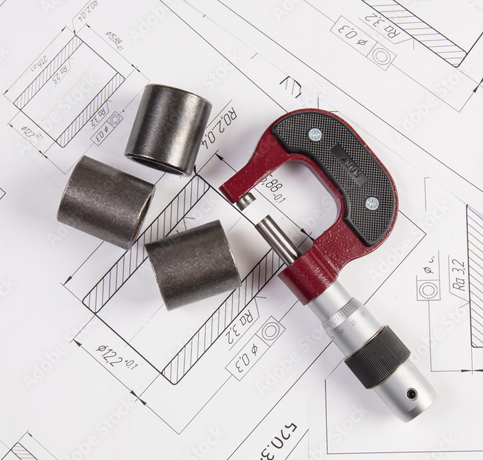

A measuring facility encompasses a diverse array of tools and equipment designed for quantifying and evaluating various parameters across different industries and applications. In the realm of manufacturing and engineering, these facilities are integral for quality control, employing instruments such as calipers, micrometers, and coordinate measuring machines (CMM) to meticulously verify dimensions and tolerances, ensuring the precision of manufactured products. Laboratories rely on specialized measuring facilities equipped with instruments like spectrophotometers and chromatographs, enabling scientists to conduct precise measurements of physical and chemical properties crucial for research and experimentation.

Construction industries utilize measuring facilities that encompass surveying equipment and laser levels, essential for accurate measurements of distances, angles, and elevations, thereby ensuring the accuracy of construction projects. Healthcare measuring facilities involve a spectrum of diagnostic equipment, including blood pressure monitors, thermometers, and advanced medical imaging devices like MRI and CT scanners, contributing to precise health parameter assessments. In information technology, measuring facilities may consist of tools for performance monitoring and network analysis, such as network analyzers and bandwidth monitors, critical for maintaining optimal system functionality.

Other Products